GEAR Spur gear & Helical gear

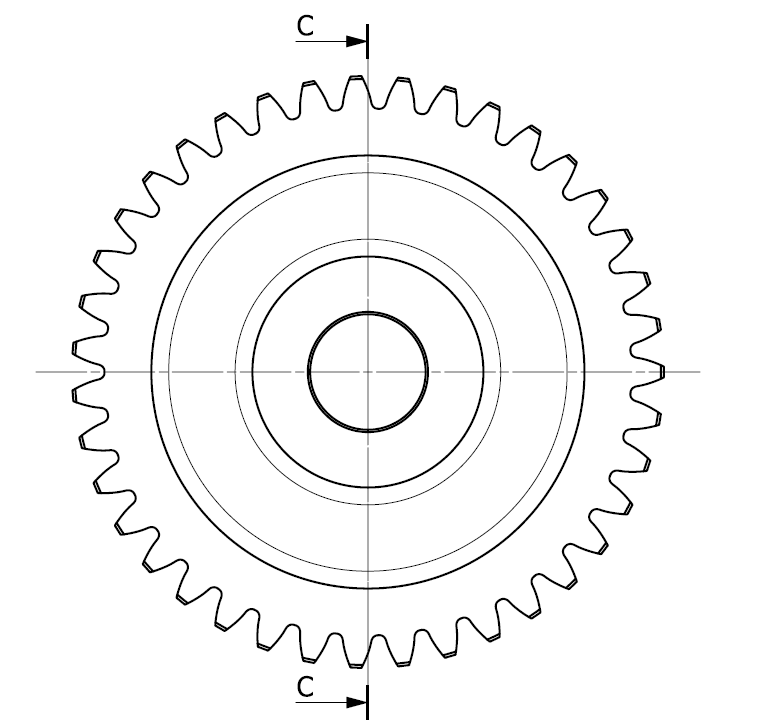

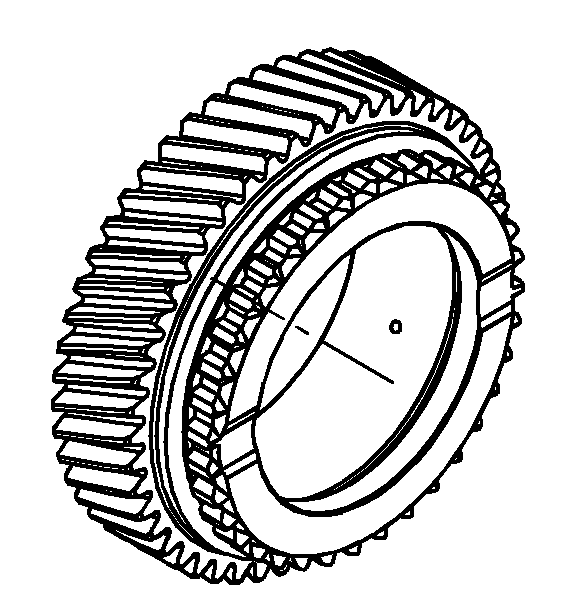

Gear wheels with straight and helical external tooth , diameter min.10 mm to max. 800mm

Production methods: slotting – Fellows method, conventional slotting machines, milling – hobbing and shaping method, CNC machines, burning – CNC wire burner, grinding – profile, generating and topological method, cap spindles from fi 30

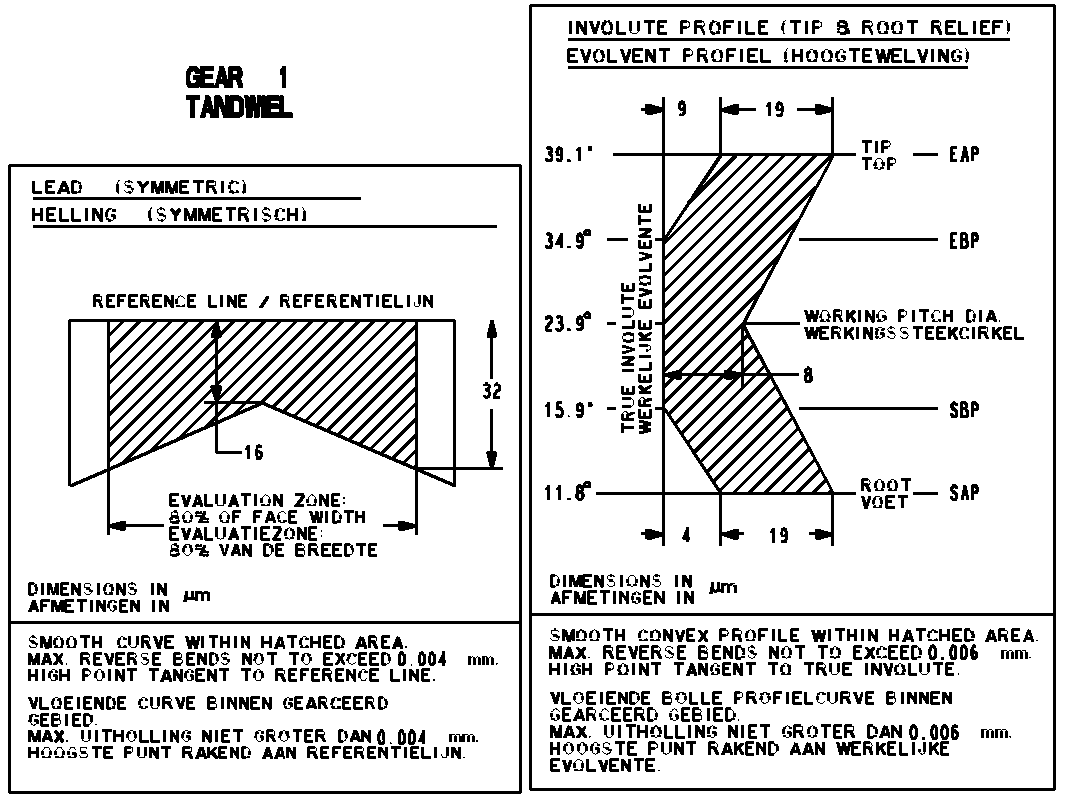

Possible modifications: line – e.g. barrel, trochoid profile – e.g. pressure angle , variables head – radius , straight , tangential foot – radius , simple , tangential

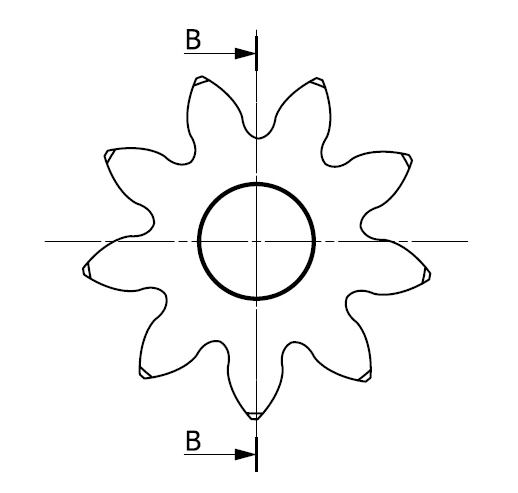

NEW: GEARS WITH EXTERNAL AND INTERNAL GEARING

: gears with a hybrid outline with increased geometrical and strength parameters. Technology for the production of gears without the need for grinding after the heat treatment process, based on “hybrid carbon-nitriding” in accordance with our patent PL 237076 “Method of gas hybrid carbon-nitriding of alloy steels in fluid bed furnaces. Eliminating the milling and grinding process and replacing it with a single chiselling-power skiving process.