GEARS PRODUCTION

GEAR WHEELS MILLED AFTER HARDENING

GEAR WHEELS MILLED AFTER HARDENING

100H Series – High Speed Hobbing with Integrated Chamfering/Deburring

The 100H Hobbing Machine Series is the next generation of the well-known P90 Series with improvements in design, functionality and operator inferface.

| Workpiece diameter, max. | 100/120* mm |

| Module, max. | 3/4* mm |

| Axial slide travel, max. | 400/800* mm |

PRECISION GENERATING GEAR HOBBING CNC 8 DIN

PRECISION GENERATING GEAR HOBBING CNC 8 DIN

RICHARDON R 200 CNC

A 6-axis, numerically controlled vertical machine for producing all possible cylindrical profiles on a cylindrical workpiece. Milling of cylindrical, conical gears and profiles with a special circular tool, a barrel.

Technical parameters:

- The outer diameter of the workpiece min. 10-300 mm

- 42CrMo 4 max.5 mm steel modules

- Axial distance Radial min. – max. 20 – 210 mm

- Vertical path max. 500 mm

PRECISION GEAR HOBBING CNC 8 DIN

PRECISION GEAR HOBBING CNC 8 DIN

LIEBHERR LC 800

- A 6-axis, numerically controlled vertical machine for producing all possible cylindrical profiles on a cylindrical workpiece. Milling of cylindrical and conical gears and profiles with a special circular tool,

Technical parameters: - minimal. Center distance: 55 mm

- Max. Center distance: 560 mm

- Max. Radial speed: 4000 mm / min

- Max. Workpiece diameter: 800 mm

- Max. Swing angle with FK 3.2: +/- 35 °

- Max. Swing speed: 0.5 ° / s

- Max. Hobbing module: 20 mm

- Max. Module profile milling: 24 mm

- more: Liebherr LC 800

GEAR POWER SKIVING 7 DIN

GEAR POWER SKIVING 7 DIN

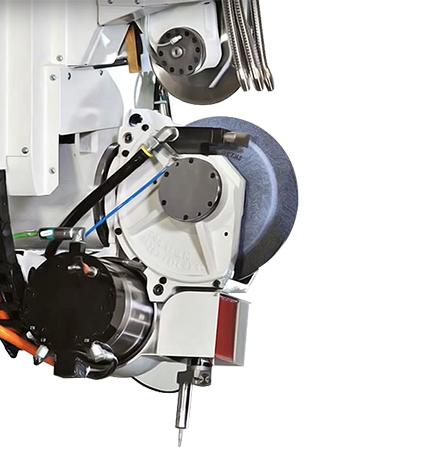

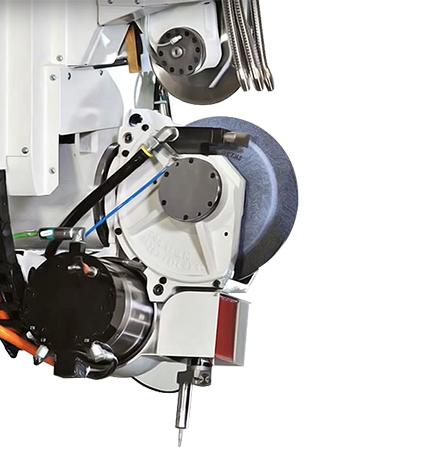

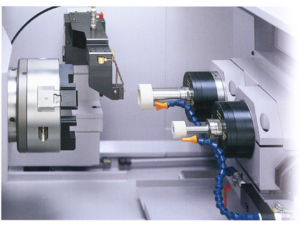

GROB G350T

Power skiving is a method of manufacturing gears and pinion shafts that is faster and more efficient than traditional methods such as helical gear slotting with profile and tooth line correction. The power skiving method is also applicable to gears with difficult exit of the tool from the workpiece. Accuracy class 7 DIN achievable.

CNC PRECISION TURNING QT200MB

CNC PRECISION TURNING QT200MB

QUICK TURN 200MB

High Performance for demanding workpiece applications

- Specifications designed to meet your production requirements – Milling function

- Tailstock travel and thrust is controlled by a servo motor

- The low thrust force ensures high accuracy turning even for small diameter shaft workpieces

- Advanced features of the Mazak SmoothG CNC

- MORE: https://www.mazakeu.com/machines/quick-turn-200mb/

CNC PRECISION TURNING CTX310

CNC PRECISION TURNING CTX310

DMG CTX 310

Technical parameters of the CNC lathe:

Working area – passage over the bed: 330 mm-

flight over the slide: 260 mm

maximum turning diameter: 200 mm

turning length in the Z axis: 393 mm

maximum diameter of the chuck: 210 mm

X axis cross travel: 160 mm

longitudinal travel of the Z axis: 450 mm

CNC PRECISION TURNING QTS350

CNC PRECISION TURNING QTS350

QUICK TURN SMART 350

offers machining diameters of 420 mm and machining up to a diameter of 102 mm. The new MAZATROL SMART control system – a dialogue programming system with unrivaled efficiency. Heavy turning – increased rigidity and speed of machining due to the use of roller guides.

- Maximum machining diameter420 mm

- Maximum machining diameter from the bar 102 mm

- more: mazak QTS 350M

CNC PRECISION TURNING MILLING QT200MSY

CNC PRECISION TURNING MILLING QT200MSY

QUICK TURN 200MSY

High Performance for demanding workpiece applications

- Specifications designed to meet your production requirements – Milling function, second spindle and Y-axis

- Second spindle utilizes a high efficency integral spindle / motor

- Standard 5000 min⁻¹ and optional high speed 10000 min⁻¹ meet the requirements of a wide variety of materials

- Advanced features of the Mazak SmoothG CNC

CNC PRECISION TURNING QT350

CNC PRECISION TURNING QT350

QUICK TURN 350

High Performance for demanding workpiece applications

- Integral spindle / motor for high accuracy and heavy duty machining. Due to no transmission with belts, pulleys or gears, the higher efficiency delivers increased power to the tool tip.

- MAZATROL SmoothC, the advanced CNC designed for ease of operation. MAZATROL SmoothG CNC also available

CNC PRECISION TURNING SV200

CNC PRECISION TURNING SV200

Unitech SV 200

Model: lathe SV 200

XZ travel: 153 x 406 mm

Spindle speed: 5000 rpm

Max turning length: 341mm

Chuck size: 210mm

Spindle bore: 52mm

Control: Fanuc

Tailstock taper: MT4

Tool size: 20 x 20 mm

Number of tools: 12

GEARS: GENERATING, PROFILE GROUND CNC

GEARS: GENERATING, PROFILE GROUND CNC

KX 300 P high precision grinding gears

generating and profile

generating and profile

machine concept

Based on a modular system in combination with the application possibilities of different tool and process technologies, user-specific, optimal production solutions can be configured. The following methods are possible:

-

continuous generating grinding

- discontinuous profile

- grindingcombination of both methods

-

header spindle (dia 30)

-

more: kapp-niles com

GEARS PROFILE GROUND CNC

GEARS PROFILE GROUND CNC

KAPP-NILES ZE 800 high precision grinding gears

Profile gear grinding machine; smallest footprint and optimal access; electrical direct drive and hydrostatic as option; external / internal gears and special profiles; highest flexibility – from drive technology .

more to –kapp-niles com

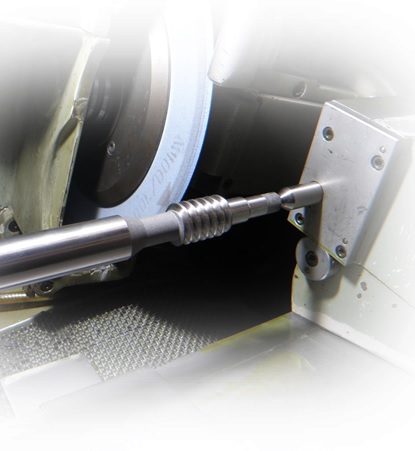

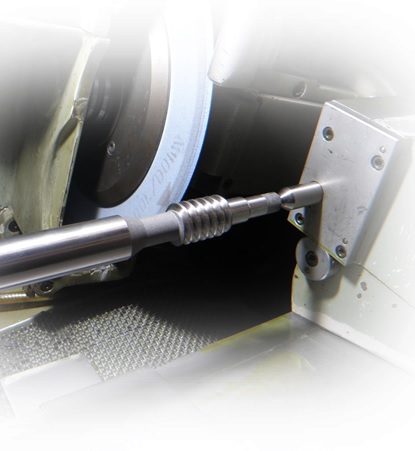

PRECISION GRINDING THRED, WORM REISCHAUER

PRECISION GRINDING THRED, WORM REISCHAUER

Thread and worm grinder Reishauer NRK

Thread diameter 3 – 200 mm

Distance between centers 700 mm

Thread length 450 mm. Thread pitch 0.3 – 80 mm

25 ° helix angle

Grinding wheel diameter. minimum maximum. 350-275 mm

Grinding wheel width 3.5 – 40 mm

Workpiece speed range, 18 steps 1-48 rpm

Grinding wheel speed 1550-1900 rpm 380V / 50 Hz, 5.5 (7.5) kW

GEARS MICRO HOLES GRINDING OKAMOTO

GEARS MICRO HOLES GRINDING OKAMOTO

Internal and face grinder IGM 15 NC III:

For machining holes and faces as well as grinding outer diameters in one clamping

Dialog control is based on a state-of-the-art microprocessor technology.

Dialogue, graphics and contour description give the user optimum comfort and safety.

Shape and cone grinding possible thanks to the simultaneous control of two axes.

Jump function in the program:

The machine goes to finishing grinding and omits the pre-treatment and dressing of the disc, which allows for a significant reduction in set-up time.

Programming the profile geometry

- more: igm-15-nc-iii

KOŁA ZĘBATE KOMPLEKSOWE SZLIFOWANIE CNC

KOŁA ZĘBATE KOMPLEKSOWE SZLIFOWANIE CNC

Vertical Mate 55

| Range of internal grinding diameter | ø30 mm(1.2 in) 〜 ø400 mm(15.7 in) |

|---|---|

| Range of external grinding diameter | 〜 ø500 mm(19.6 in) |

| Grinding length | ID 300 mm(11.8 in) / OD 325 mm(12.7 in) |

| Work spindle swing | ø550 mm(21.6 in) |

| Workpiece height | 450 mm(17.7 in) [including fixture] |

| Max. loading weight on work table | 500 kg(1,102 lb) [including fixture] |

| Grinding spindle rotation speed | 15,000min-1 |

| Floor space (W×D) | 2,715 mm(106.9 in) × 4,110 mm(161.9 in) |

GEARS – CNC OUTER DIAMETER GRINDING

GEARS – CNC OUTER DIAMETER GRINDING

Precision CNC ROBBI OMICRON 3210

roller grinder with active MARPOS measurement

- The CNC versions were developed in response to needs for medium-high production volumes.

- Equipped with the latest-generation of SIEMENS 840D sl control system.

- The work cycle can be optimised in-process with geometrical and working parameters.

- The machine can be equipped with automatic measurement devices to process complex components.

- The CNC version allows the operator to profile the grind wheel in relation to geometries specifically created for the type of production required.

- High precision crowning operations can be performed by equipping the machines with a third interpolated axis and a bespoke software for this processes.

more:Robbi

GEARS Micro hardness testing CHD

GEARS Micro hardness testing CHD

Micro hardness testing CHD

- Measurements of gear in a tooth cross-section

- Vickers-DIN EN ISO 6507, ASTM E-384, ASTM E92

- KnoopDIN EN ISO 4545, ASTM E-384, ASTM E92

- BrinellDIN EN ISO 6506, ASTM E-10

- more:QNESS Q10

GEAR MEASUREMENTS 3D CNC

GEAR MEASUREMENTS 3D CNC

Coordinate measuring machine

System XO87-1000 X3M25 GEO

X axis: 800mm

Y axis: 1000 mm

Z axis: 700 mm

System XO87-1000 X3M25 GEO

X axis: 800mm

Y axis: 1000 mm

Z axis: 700 mm

GEAR MEASUREMENTS 4D CNC

GEAR MEASUREMENTS 4D CNC

WENZEL WGT 400

CNC machine for measuring gears

Diameter of parts min./max. 5 – 400 mm

Inner diameter of the wheel min. > 12 mm

Range of modules From 0.5 mm

Wheel width max. 500 mm

Inclination angle max. <90 °

Accuracy of control of gears according to VDI / VDE 2612/13, Group I

more: Wenzel WGT 400

GEAR MEASUREMENTS 3D CNC LH108

GEAR MEASUREMENTS 3D CNC LH108

GEARS 3D measuring machine

optional additional measurements of gears up to 800 mm diameter

more: Wenzel LH 108

GEAR CAD CAM ERP BARCODE

GEAR CAD CAM ERP BARCODE

Integration of CAD design systems with CAM machine programming and ERP production management

Tracking the production process using barcode readers

CNC MILLING IN 4 AXES NEXUS 410A

CNC MILLING IN 4 AXES NEXUS 410A

Technical specifications

Travel length in the X axis 900 mm

Travel length in the Y axis 410 mm

Z axis travel length 570

The VERTICAL CENTER NEXUS 410A-II Vertical Machining Center combines advanced technology, productivity and value for a wide variety of applications. The machine is built with more productivity-enhancing features than any other vertical in its class. Equipped with the Mazatrol Matrix Nexus CNC, this control provides conversational or EIA programming, giving the capability and productivity necessary for today’s technology driven shops.

MACHINE CHARACTERISTICS:

- Performance enhancing Intelligent Machine features

- Mx Roller Guide Technology on all axes

- Ergonomic control swings for easy operator viewing

- High accuracy and productivity for a variety of industry applications

- Easy integration of articulated robots for process automation

MILLING CNC IN 3 AXES HV 710

MILLING CNC IN 3 AXES HV 710

XV 710 vertical machining center

Working area: X axis 710 mm Y axis 450 mm Z axis 460 mm

distance spindle nose-table min./max. 150/610 mm

Working feed (infinitely adjustable) 1 … 10,000 mm / min

Rapid traverse X / Y / Z 30 m / min

Work spindle: Speed 10.000 / min. Power (S6 40%) 13.5 kW

Torque (S6 40%) 95 Nm

SK 40 tool holder

Workpiece carrier:

Clamping surface 760 x 420 mm max.

table load 700 kg 5 T-slots

Tool changer 24 places

Chip conveyor

Switch cabinet with heat exchanger

Movable knob

Workplace lighting

Central lubrication

MILLING CNC IN 4 AXES VTC 800 20HD

MILLING CNC IN 4 AXES VTC 800 20HD

CNC machining center for the production of bodies and other elements of gears

Work space

Table height from the posture-870 mm

Table working surface (transverse) -2.500 mm

Working surface table (longitudinal) -820 mm

Cross slide (longitudinal) of the X-2,000 mm axle

Column (transversal) of the Y-800 mm axis

Spindle head (vertical feed) of the Z-720 mm axis

Maximum spindle speed (standard) 18,000 min-¹

Fast travel (X axis) 50 m / min

Fast travel (Y axis) 50 m / min

Fast travel (Z axis) 50 m / min

The size of the T-slot (rotary table) 18mm +0.018 -0.000

Table length 2,500 mm

Table width 820 mm

Automatic tool changer

Tool magazine capacity (standard) 30

Tool holder CAT-40 / MAS BT-40

Machine width4,480 mm

Machine depth3,575 m

MILLING CNC IN 4 AXES CMX 1100V

MILLING CNC IN 4 AXES CMX 1100V

CMX 1100 V

Oparty na rozwiązaniach CMX V – od teraz z IoTconnector i bezpośrednim układem pomiarowym w standardzie

Maks. przesuwy w osi X 1 100 mm

Maks. przesuwy w osi Y 560 mm

Maks. przesuwy w osi Z 510 mm

Maks. długość obrabianego przedmiotu 1 400 mm

Maks. szerokość detalu 560 mm

Maks. wysokość obrabianego przedmiotu 630 mm

Maks. ciężar detalu 1 000 kg

Oparty na rozwiązaniach CMX V – od teraz z IoTconnector i bezpośrednim układem pomiarowym w standardzie

PRECISE CNC MILLING IN 5 AXES GROB G350T

PRECISE CNC MILLING IN 5 AXES GROB G350T

GROB G350T

5-axis universal mill-turn machining center

The compact G350T mill-turn machining center enables machining of smaller parts from practically any material in just one setup.

Benefit from the process reliability and durability of the GROB machine concept and see for yourself the diverse range of applications our innovative G350T machining center covers.

GROB G350T

5-axis universal mill-turn machining center

GEARS – ULTRASONIC WASHING, PHOSPHATED, PRESSURE ANTI-CORROSIVE PROTECTION

GEARS – ULTRASONIC WASHING, PHOSPHATED, PRESSURE ANTI-CORROSIVE PROTECTION

GEARS MARKING LASER ENGRAVING

GEARS MARKING LASER ENGRAVING

Marking and describing products

GEARS – WASHING, DRYING, ANTI-CORROSION SPRAY MAINTENANCE

GEARS – WASHING, DRYING, ANTI-CORROSION SPRAY MAINTENANCE

Washing, drying, anti-corrosion protection

GEARS MARKING IMPACT ENGRAVING

GEARS MARKING IMPACT ENGRAVING

GEARS Carburizing Carbonitriding Hardening